SIP structures, home manufacturing and construction

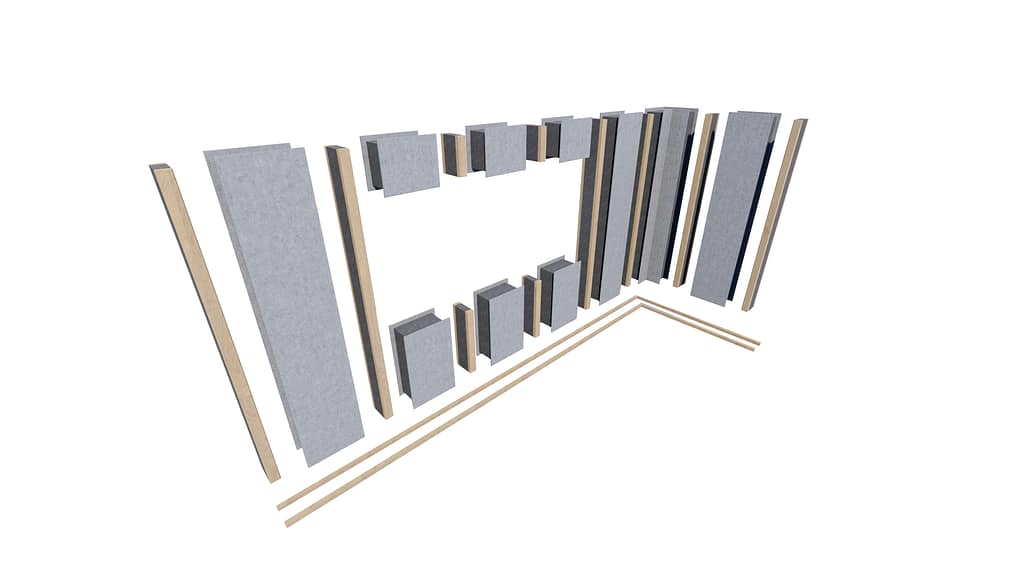

SIP panel manufacturing

Manufacturing of double T-beams

Designing

Supply of construction materials

Innovative manufacturing, construction materials, and construction company.

Manufacturing of SIP panels and double T-beams

Construction services, from individual design and document management to handover of keys.

By choosing construction materials from SHELLBAU, you will receive high-quality, energy-saving, and environmentally friendly materials that fit your budget and ensure that your home maintains its value and functionality for a long time.

Focus on sustainability, efficiency, and environmental protection.

Project "Granatas"

113.71/m2

Project "Karneolitas"

113.46/m2

Project "Turmalinas"

79.56/m2

Project "Topazas"

76.1/m2

Project "Ametistas"

73.3/m2

Project "Citrinas"

71/m2

Project "Agatas"

41.3/m2

Project "Apatitas"

39.9/m2

SHELLBAU

12 years of experience SIP houses build industry

We are manufacturers of SIP structures and wooden beams. We create innovative and reliable solutions for home construction. Committed to ensuring the success of your projects, we offer various solutions for building construction.

SIP panels 600x3000mm (Structural Insulated Panels) are products made from sheets with insulating material in between. You can choose from two types of sheets (Oriented Strand Board (OSB) or Cement Bonded Particle Board (CDP)) and insulation materials such as polystyrene foam, Neopor (a gray-colored polystyrene foam with improved thermal insulation properties enhanced by the addition of graphite to the raw polystyrene), or dense wool. The insulation thickness can range from 150mm to 400mm. *Cement bonded particle boards, compared to OSB, offer better fire resistance, resistance to water, mold, rodents, and mechanical strength. SIP panels are suitable for all house constructions—walls, floors, and roofs.

We also specialize in the production of wooden double T-beams. The beams are made from wooden flanges, top and bottom, which are connected by a 10mm or 12mm OSB board, depending on the construction. Wooden beams can be selected from 150 to 500mm in height. For the Shellbau system, we manufacture insulated double T-beams, which are used for interconnecting SIPs and for the roof structure.

200+

Projects finish

12+

Years of experience

6 mth.

Dream home in 6 months

50 year

Warranty

2.1 SHELLBAU An innovative production, construction materials, company.

2.2 PRODUCTION Manufacturing of SIP panels and double-T beams.

2.3 CONSTRUCTION SERVICES Construction services, from individual design and document management to key handover.

2.4 CONSTRUCTION MATERIALS Choosing construction materials from SHELLBAU ensures high-quality, energy-efficient, and environmentally friendly materials that fit your budget. These materials also guarantee that your house will maintain its value and functionality over the long term.

2.5 ECOLOGY A focus on sustainability, efficiency, and environmental protection.

2.6 INDIVIDUAL CONSULTATIONS We offer personalized solutions that meet your unique needs and expectations.

SHELLBAU - GUARANTEE OF QUALITY

Since the beginning of architecture, people built their homes using various materials: Since the beginning of architecture, people built their homes using various materials: The main purpose of houses was to protect against various dangers, natural phenomena, heat, and cold. Gradually, it evolved into building not only stronger and more durable homes, but also giving them a unique and attractive appearance. Over time, construction processes have greatly improved, and although some of the mentioned materials are still used today, there are many new high-quality materials used in home construction and finishing.

To ensure the best results, modern projects have high demands for construction materials, based on structures and technical properties. Therefore, aiming to meet market expectations and utilising more than 12 years of experience, the Shellbau team offers a unique home construction system and a wide range of quality finishing materials, reflecting the diversity of needs and allowing you to enjoy the comforts of modern life.

Turn your boldest visions into reality with the Shellbau home construction. It is an advanced home construction system developed by us and patented in Europe. We want to inspire our clients to choose creative and modern solutions, so don’t hesitate to contact our team – we will advise you on all home construction matters. Our philosophy: Genius lies in simplicity.

Let us take care of the harmony of materials and create the future together.

Stabilumas

Shellbau offers you sustainability and exclusivity

We have been working for over 12 years, and our goal has always remained the same: to offer our clients the highest quality services from A to Z in the market.

The Shellbau system is characterized by the following advantages

Homes built from “Shellbau” brand constructions stand out with a 12% larger usable area compared to other homes of the same dimensions, due to the thinner walls allowing for more efficient use of space.

The “box” of the house can be constructed in 14 days.

A fully finished house can be constructed in 6 months.

The “Shellbau” brand home construction comes with a 50-year warranty.

Due to all the aforementioned reasons, banks and insurance companies view the financing of the project very favorably.

Why ShellBau?

Advantages of the Shellbau system:

We are the only manufacturers who use the same-sized Shellbau 600x3000x(100-300) mm panels for all house structures – walls, floors, and roofs. This offers you the following benefits:

Houses from Shellbau structures have a 12% larger usable area compared to homes of the same dimensions, as it saves usable space due to thinner walls.

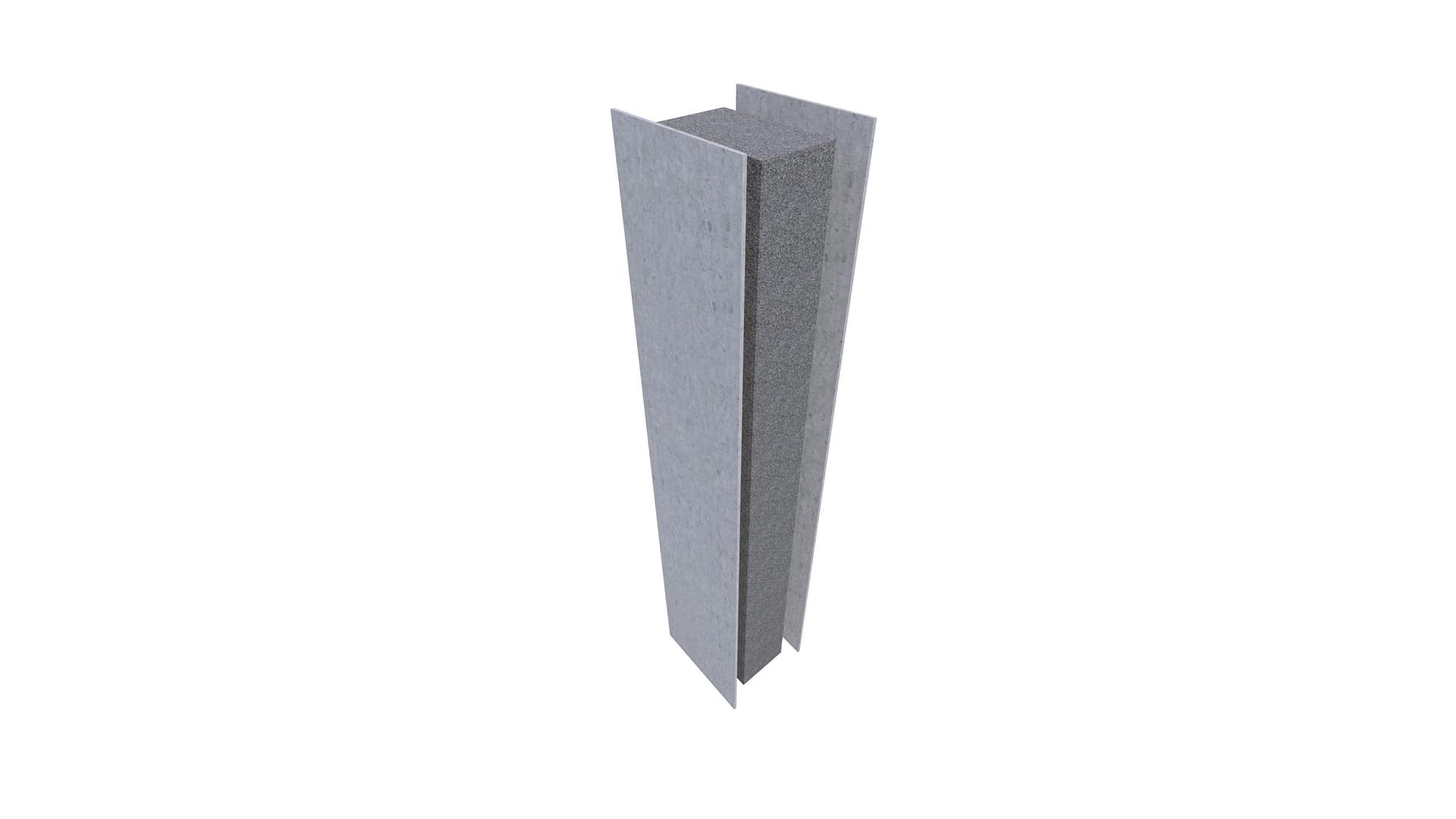

Panels are manufactured using polystyrene foam with cement particle board on both sides. Beams and fittings are made of wood.

The panel surface is covered with cement particle board and polystyrene foam, so it does not ignite during a fire and does not contribute to spreading flames through the construction.

The assembly process does not use the "wet" technology, so both exterior and interior finishing can start as soon as the main structures are assembled, and construction can proceed at any time of the year.

To protect wooden structural parts from atmospheric effects during installation, they are fully sealed.

Shellbau elements are lightweight – the heaviest component weighs around 65 kg. Therefore, for example, the weight of an 80 m² house is about 4 tons.

Shellbau is known for its high structural strength and low weight. Thanks to the extra strong bonding of the sandwich panels, it can withstand an axial force of 3 t/m2 and a lateral force of 2 t/m2 (for flat roofs, a resistance of 0.4 t/m2 is sufficient);

Thanks to the shell construction of Shellbau, the weight is evenly distributed on the foundation, avoiding concentrated loads. Since the materials used are lightweight, the house will not settle. This type of construction places lower demands on the foundations compared to brick houses.

Various architecture

No cold bridges

Complete building structure

Houses from Shellbau structures have a 12% larger usable

A house can be built in just a few days

Shellbau home construction comes with a 50-year warranty

Indelible experiences

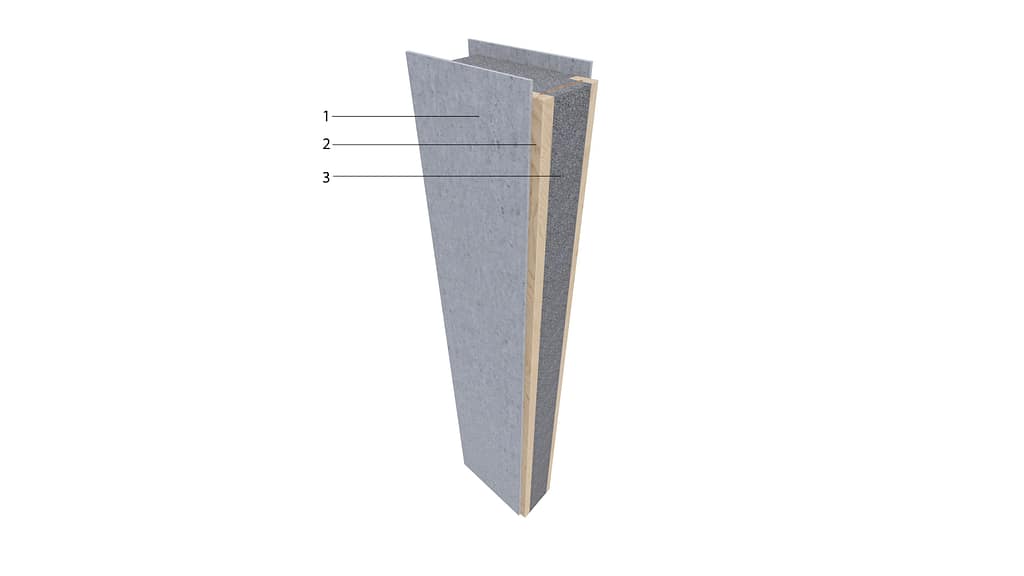

ShellBau panel

The U-value is the insulation value of a structural part (e.g. a roof or a wall). U is the symbol for heat transfer coefficient. The U-value is expressed in W/m²K and depends on individual material layers that make up the structural part (the thickness of individual materials and the lambda value). The U-value of a structural part indicates how much heat is lost per second for each square meter when the temperature inside and outside differs by 1°C.

Shellbau has three layers: two durable cement slabs with an extremely efficient insulating polystyrene foam board sandwiched between them.

- Composition of a cement slab: 63% wood particles, 25% cement, 10% water and 2% additives

- Polystyrene foam EPS 100N

- I-beam (connecting part)

The Shellbau building construction system consists of two elements, namely, SIP (Structured Insulated Panel) and wooden I-beams. These interconnected elements create a load-bearing frame structure. Then, the cement slab, forming the external and internal SIP surfaces, integrates all of this into a shell structure, providing spatial stability and strength to the building. The system has no cold bridges and complies with the energy efficiency class A++ requirements, according to European Parliament and Council Directive 2002/91/EC.

Shellbau has three layers: two durable cement slabs with an extremely efficient insulating polystyrene foam board sandwiched between them.

- Composition of a cement slab: 63% wood particles, 25% cement, 10% water and 2% additives

- Polystyrene foam EPS 100N

- I-beam (connecting part)

A++ House requirements: U-value |

Shellbau U-value |

Walls, floors 0.1 | Walls 0.098 |

Roof 0.08 | Roof 0.075 |

Floors 0.1 | Floors 0.098 |

Windows 0.7 | Windows 0.7 |

Door 0.7 | Door 0.7 |

*U-value – heat transfer coefficient;

ShellBau - technology that fascinates

Shellbau

The spatial rigidity of the Shellbau structure is obtained through the interaction of an integrated frame, cement slabs, and polystyrene foam. High energy efficiency is ensured by a tight external insulation layer without cold bridges. Polystyrene is glued with adhesive, and gaps are sealed with sealant. Lightweight components – two persons, without the use of lifting machinery, can quickly assemble the building. Standardised components allow for diverse and individual architecture.

The Shellbau building construction system consists of two elements, namely, SIP (Structured Insulated Panel) and wooden I-beams. These interconnected elements create a load-bearing frame structure. Then, the cement slab, forming the external and internal SIP surfaces, integrates all of this into a shell structure, providing spatial stability and strength to the building. The system has no cold bridges and complies with the energy efficiency class A++ requirements, according to European Parliament and Council Directive 2002/91/EC.

Shellbau offers you sustainability and exclusivity

Have questions?

Frequently Asked Questions

Questions frequently asked by customers.

Yes, a SIP house is durable. They are made from high-quality materials that are resistant to moisture, cold, and fire. SIP panels are sturdy and can withstand heavy loads.

Yes, a SIP house is fire-resistant. SIP panels are made from cement bonded particles, which are non-combustible. Their fire resistance classification is B-s2,d0.

Additionally, SIP panels are tightly sealed, preventing fire from spreading quickly between them. This also enhances their fire resistance.

Yes, the company “ShellBau” assists with managing the paperwork required for home construction. The company’s specialists consult clients on the process of obtaining construction permits, help prepare the necessary documents, and represent clients in municipalities and other institutions responsible for issuing construction permits.

“ShellBau” also helps design the house and select the appropriate materials. The company’s specialists have experience working with SIP home construction technology and can help clients choose the optimal solution based on their needs and budget.

Yes, ShellBau homes are warm. The thermal conductivity of SIP panels is low, so they retain heat very well. The thermal conductivity of SIP home walls is about 0.098 (U value), which is significantly lower than that of traditional brick or frame house walls.

This means that ShellBau homes require less heating energy, which helps save money.

The first step in building a ShellBau house is project preparation. The designer, together with the client, discusses the client’s needs and expectations, and then prepares a project that meets all requirements.

SIP panels are manufactured in the factory. The panels are made according to the client’s project and meet all requirements.

Construction begins with the foundation. The foundations must be strong and meet all requirements.

Then SIP walls, roof, and other structures are built.

External finishing works start with the installation of the roof covering. Then facade panels or finishing bricks are installed.

Engineering works include electrical installation, plumbing, and sewage system installation.

Interior finishing works include installing walls, ceilings, and floors.

Document preparation for handing over the house.

Now you can start living in your new ShellBau home!